|

|

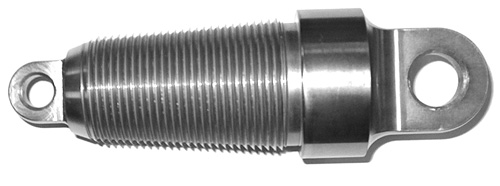

FIXED HEAD POLYETHYLENE PIPE & INNERDUCT PULLING EYES

|

| Design Features |

These solid steel pullers are machined with a tapered buttress thread to grip the inside wall of polyethylene pipe and innerduct by simply screwing them into the opening. When properly installed, the gripping power of the puller is stronger than the tensile strength of the pipe or innerduct. Pullers are installed quickly and easily with a screwdriver shaft or metal rod.

Typical uses are:

1. Pulling polyethylene water pipe, gas pipe and cable ducting with a vibratory plow.

2. Installing innerduct inside large cable duct.

3. Installing pipe and ducting in Horizontal and Directional Drilling applications.

DP-125L Shown

|

|

| LUG STYLE PULLING EYES |

| Model No. w/o Rear Lug |

Model No. with Rear Lug |

Nominal Duct Size |

Min. I.D. |

Max. I.D. |

| DP-075 |

DP-075L |

3/4" |

0.72" |

0.93" |

| DP-100 |

DP-100L |

1" |

0.94" |

1.15" |

| DP-100A |

DP-100AL |

1" Irrigation Pipe-SDR 21 |

| DP-125 |

DP-125L |

1 - 1/4" |

1.26" |

1.44" |

| DP-150 |

DP-150L |

1 - 1/2" |

1.48" |

1.66" |

| DP-200 |

DP-200L |

2" |

1.91" |

2.08" |

|

| REPLACEMENT REAR LUGS |

| Model No. |

Fits Pulling Eye |

Thread Size |

| DPL-1 |

DP-075 |

3/8" X 16 |

| DPL-2 |

DP-100, DP-125 |

1/2" X 13 |

| DPL-3 |

DP-150, DP-200 |

5/8" X 11 |

|

| Directional Boring Swivels |

Gold Series

Extreme Duty

Directional Boring Swivels

BorePro's Extreme Duty Pullback Swivels are specifically designed to swivel, under high tension loads, in the harsh environment of Directional Boring. Additionally, they are also used in overhead and other underground applications that require a reliable, high quality swivel. All swivels in this series use a side mounted grease fitting for easy lubrication and a multiple sealing system to retain the lubricant and repel external contaminants.

The structural components of these swivels, including the clevis pins, are manufactured from high strength, quenched and tempered, chrome-moly steel and will withstand loads of at least 3 times the listed Safe Working Loads.

Due to their unique spindle design and bearing configuration, these Extreme Duty Swivels will handle higher side loads than standard ball bearing type swivel. However, please note that a swivel is not a universal joint and is designed to be used under tension in a straight line. It is recommended that you select a swivel with a larger work load capacity than the drilling machine.

|

| Directional Boring Swivels |

| Model No. |

Work Load* |

BRKG. Strength* |

Body Diameter |

Jaw Opening |

Pin

Diameter |

| DB-1625 |

9,000 |

27,000 |

1 5/8" |

3/4" |

5/8" |

| DB-2000 |

12,000 |

36,000 |

2.00" |

13/16" |

3/4" |

| DB-2250 |

15,000 |

45,000 |

2 1/4" |

7/8" |

3/4" |

| DB-2500 |

22,000 |

66,000 |

2 1/2" |

1.0" |

7/8" |

| DB-3000 |

32,000 |

96,000 |

3.00" |

1 3/8" |

1 1/8" |

| *PSI |

|

|

|

|